Metal Sintered Filter Medium

| Product Name | Compositions | Micron Rate |

|---|---|---|

| Sintered Wire Mesh | Woven Wire Mesh | 1-300um |

| Sintered Metal Fiber Felt | Non-woven Metal Fiber | 5-80um |

| Sintered Metal Powder | Metal Powder Particle | 0.5-80um |

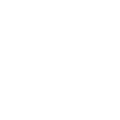

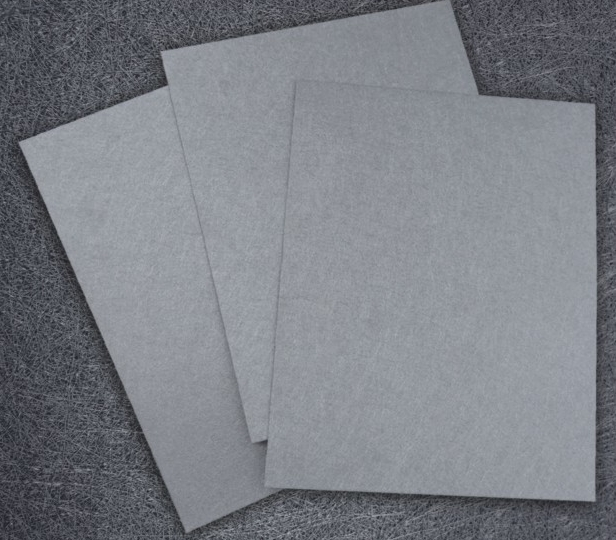

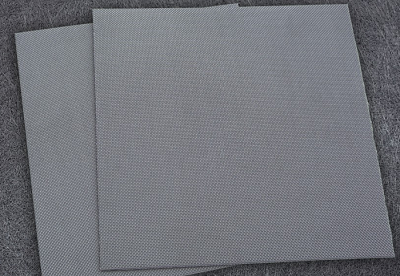

Sintered Wire Mesh

Product introduction

It is composed of several layers of wire mesh, sintered to be in vacuum oven, by laminating for specified times, to create a newfilter material with higher strength and rigidity.Filter rate:1-300um(same to wire mesh)

The layer is changed according to the working condition or customer’s requirement. It can be standard 5 layers, also can be 3 layers, 4 layers, 6 layers and more than 10 or 20 layers

Application case:

1.High temperature and strength chemical filter element with most common 5 layer sintered mesh;

2.Ship ballast water system filter element with 3 layer sintered mesh;

3.Pharmaceutical machine plate filter with 6 layer sintered mesh;

4.Water treatment cartridge filter with perforated sheet sintered with wire mesh;

5.Gas distribution fluidized bed with multi layer sintered mesh;

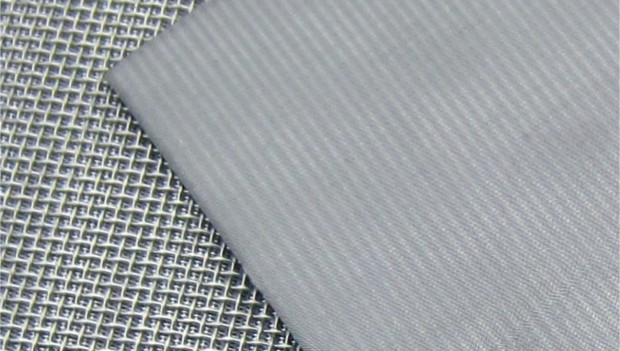

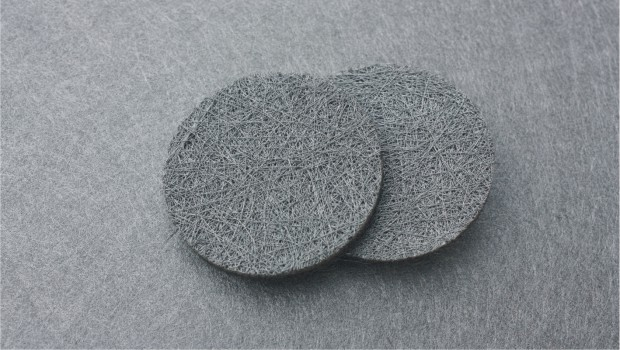

Sintered Metal Fiber Felt

Product introduction

It is made of extremely fine steel fiber (micron grade) by sintering in high temperature after special non-woven matching and laying.

Filter rate:5-80um

Application case:

1.Pleated fiber felt filter element,polyester melt purification of high temperature and great viscosity, in chemical fiber and membrane industries;

2.High temperature dust-removing cartridge filter;

3.High efficiency filtration up to 99% of methyl alcohol element filter;

4.Thickening fiber felt in vehicle oil volatilizer of heating equipment;

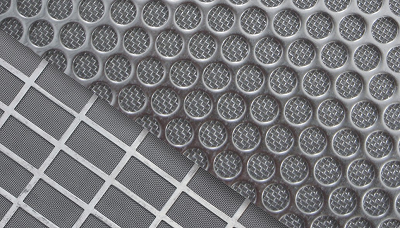

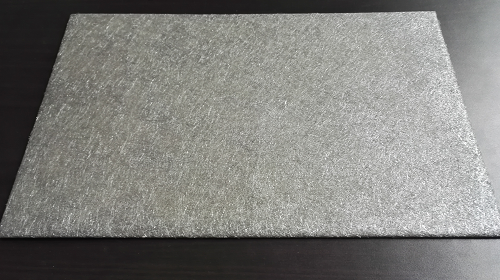

Sintered Metal Powder

Product introduction

The metal microporous filtration material is made of irregular metal powder processing ,formed by isostatic pressing, molding, extrusion molding, and then by sintering in high temperature to be. It has good permeability filtration performance and high filtration precision, and a certain strength and toughness

Application case:

pharmaceutical, petroleum, water treatment, food, biological engineering, chemical, metallurgical, environmental protection, as the filter material, porous electrode materials, sound-absorbing materials, damping materials, divergent cooling material, catalyst and catalytic materials, antifreeze and cushioning material etc.

Home

subscription

Pay attention to qr code

Get the latest information

- Liben Group Brand Name